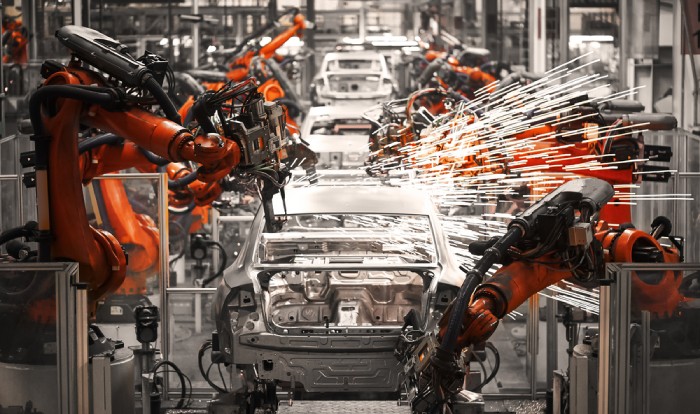

As the world of technology advances, we’ve seen a gradual increase in the presence of machines or robots through innovations like assembly line automation. Take manufacturing companies, for instance. For some time now, they have been using different forms of automation to ease the process of manufacturing, while at the same time reducing costs. Automation can involve anything from robots that weld and paint to machines that pick and pack or dispense the right amount of glue or fasteners.

In many cases, automation has proven to be more efficient and accurate than human counterparts. For example, robots don’t get tired and can work for longer hours without making any mistakes. They can also be easily programmed to carry out specific tasks in warehouses and manufacturing plants.

The Pros and Cons of Automatic and Manual Assembly Lines

While automation has many advantages, there are still some companies that rely on manual labour.

Here is a look at the pros and cons of both types of assembly lines:

- Manual assembly lines are slower and less accurate than automated lines. They also require more manpower, which can be costly.

- Automated assembly lines are faster and more accurate than manual lines. They also require less manpower, which can save money in the long run.

In the end, it is up to the company to decide which type of assembly line is best for them. However, most experts agree that automation is the way of the future and that companies should consider it for their assembly lines.

The Types of Automation Used in An Assembly Line

Automation has become an important part of assembly lines. It helps speed up the process and produce high-quality products. There are many types of automation, each with its own set of advantages, whether it’s a hard, programmable, or soft type of automation in the assembly line.

Here is a look at some of the most common types:

- Robots are widely used in assembly lines because they are efficient and accurate. They can work for longer hours without making mistakes.

- Machines are used to dispense the right amount of glue or fasteners, among other things. They are precise and can save time and money.

- Automated Guided Vehicles (AGVs) are used to move materials or products from one place to another. They are small vehicles that move along a pre-programmed path and can transport anything from boxes to pallets.

- Industrial Internet of Things (IIoT) is the term used to refer to all the machines, computers, sensors, and other devices that are connected through the internet.

- Collaborative robots, or cobots, are robots that work collaboratively alongside humans. They are safe to work around and can be used for a variety of tasks.

Each type of automation has its own advantages and disadvantages, which can offer unique gains to an assembly line relative to their respective industries. However, a company with the size and scalability to afford automation should consider it as a viable option towards growth.

The Advantages of Assembly Line Automation

There are many advantages to using an automated assembly line. Here are some of the most important ones:

- Speed – Automated assembly lines are much faster than manual lines. This means that products can be produced at a faster rate and with less manpower.

- Accuracy – Automated assembly lines are more accurate than manual lines. This means fewer mistakes are made and products can be produced more efficiently.

- Less Labour – Automated assembly lines require less manpower than manual lines. Since robots do not get tired, they work for longer hours without making mistakes. They can also carry out specific tasks that would otherwise have to be done manually by multiple people.

- Safety – Automated assembly lines are safe to use. They do not require any manual labour with dangerous applications.

- Cost – Automated assembly lines are more expensive than manual lines. However, they save money in the long run because they are more efficient and accurate.

The Application of Collaborative Robots in an Automated Assembly Line

One of the advantages of cobots is that they can be used for both manual and automated tasks. This makes them a versatile tool for assembly lines. They can be used to help humans with tasks that are too difficult or dangerous for them to do manually.

This is a recent trend which has been taken up by a lot of companies, primarily because of the rewards it offers, especially in the long run. Any person who has done an assembly line job knows that sometimes the monotonous work can be difficult, so having automated machines or robots that can take over part of your job can be a relief.

As a business owner, manifesting the vision of utilising automated assembly lines can transform the way tasks are conducted. The main advantage is that there’s less need for human labour, leading to reduced costs in the longer term. Automated machines and robots can also do the job more accurately than a human, so you’re less likely to have any defective products.

Another benefit is that it makes the work environment safer because there’s no need for manual labour. If anything, human workers can focus more on critical tasks as cobots take on the monotonous steps in the production process.

Finally, automated assembly lines are faster than manual ones, so churning out more products in a shorter amount of time becomes a reality. Overall, there are many advantages to using an automated assembly line in your company. So, if you’re looking for a way to improve your production process then this might be the solution for you.

Using pioneering collaborative cobots, your business can tap into the potential that the future offers and implement it into the processes of today.