Our client, CR Solutions Ltd, was called upon by Rolls Royce to provide a system to optimise the process of maintaining and servicing turbofan engines.

The challenge

For maximum efficiency of an aircraft turbofan engine, the gap between the tip of the fan blades and the engine inner surface must be at an optimum. Through normal wear and tear and as a consequence of repeated heavy landings when the engine might become distorted in shape, the tip of the blades can come into contact with the inner surface thus making the gap excessively large or irregular.

Until now the inner surface of the engine had to be machined out, refitted and reground by hand, relying heavily upon the expertise and experience of the operator to achieve the right finish – rather like filling and machining out dents in car bodies. For the aircraft operator, this part of the maintenance programme is both costly and time-consuming.

Solution

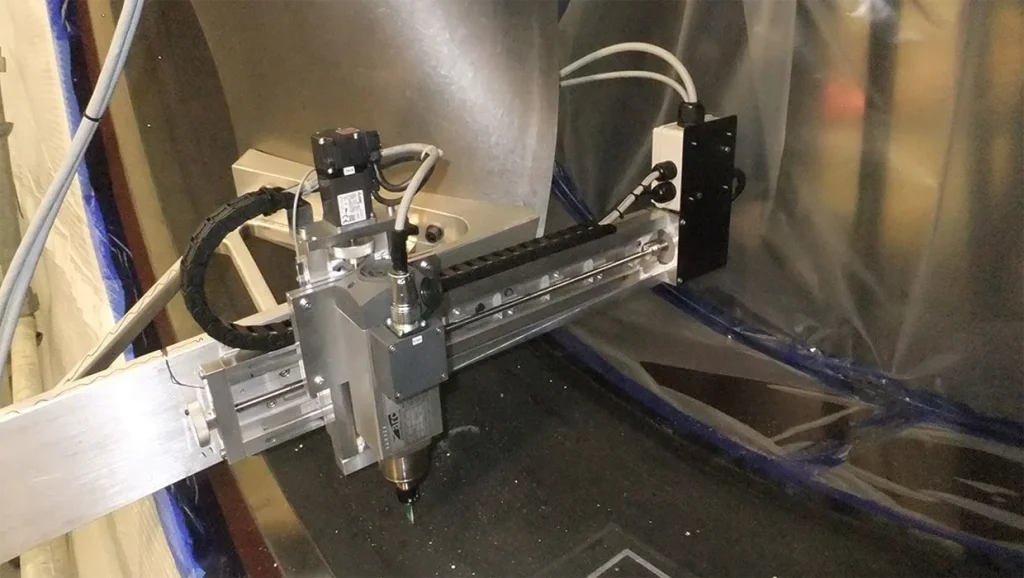

To improve the process, a number of assemblies have been designed and constructed which contain customised linear slides from LG Motion which are able to meet the exacting space and performance requirements for this challenging application.

The equipment can be deployed in engines while still mounted on the aircraft, following removal of the blades. Now the new inner surface can be machined using the engine rotor while turned manually. This new process allows a considerable amount of time and costs to be saved.

The complete assembly shown above comprises of a spindle motor with a grinding tool mounted on a servo-controlled leadscrew arrangement that allows the grinding tool to be controlled in the Y and Z directions.

Using the engine rotor eliminates any problems of eccentricity and both the cutting depth and position can be precisely determined and maintained.

If you are looking for a dedicated partner to work alongside for your electro-mechanical motion project, get in touch.

We’ll work with you to develop the best solution for your specific challenge, no matter how complicated.

Arrange a visit and meet the team: